Electrical Engineering

The Centrepiece of EPLAN Engineering

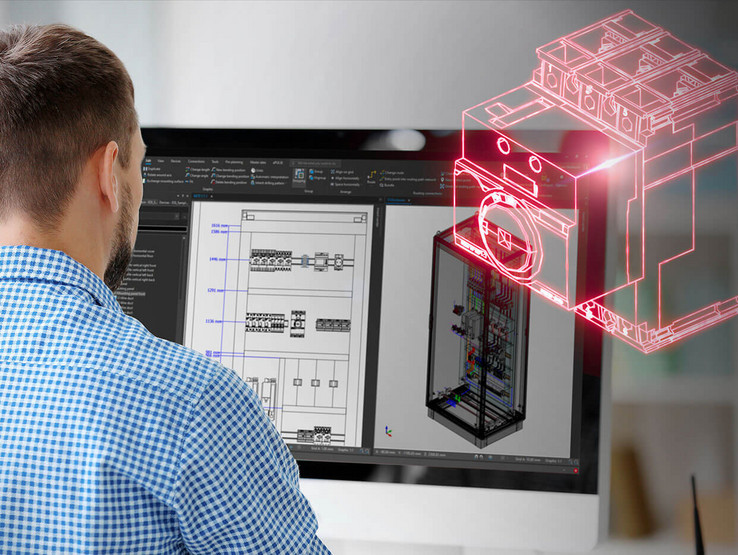

Electrical engineering design is a complex field, particularly as several people are often working in various disciplines on the same project. Electrical engineering data must also be usable for other departments such as order processing and manufacturing. At the same time, electrical engineering is always under time pressure, must deliver on time and always keep an eye on incurred costs. EPLAN offers you an integrated software solution from a single source for efficient electrical engineering across processes.

Overview: Electrical Engineering’s Tasks and Challenges

Electrical engineers are faced with a variety of tasks and challenges that must be mastered every day. EPLAN solutions are always available to support you.

Challenges for Electrical Engineering

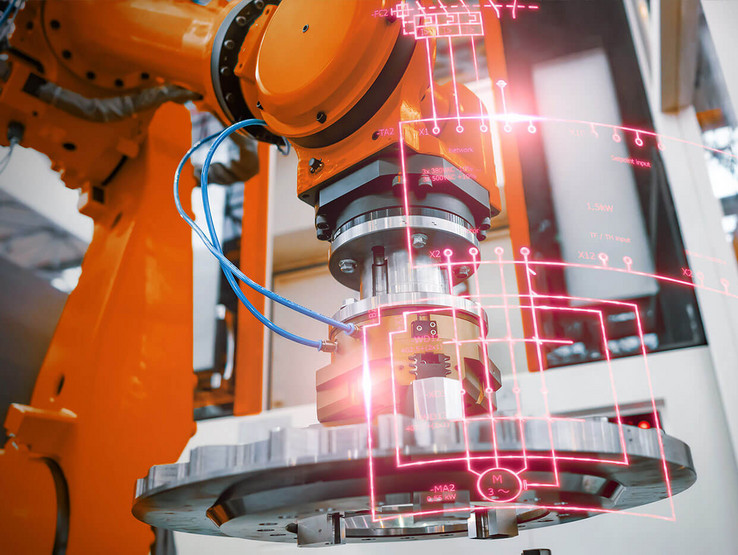

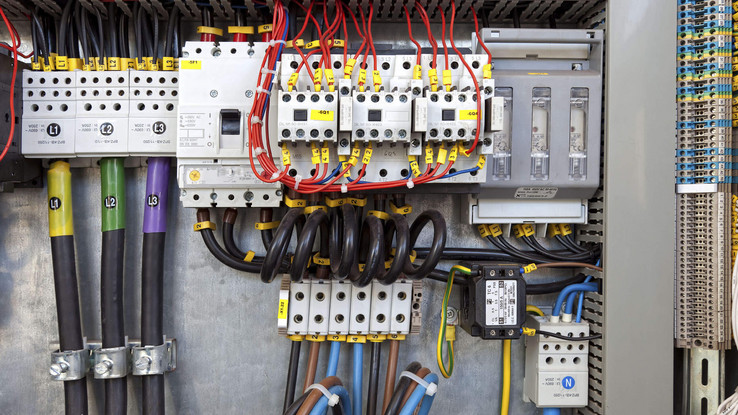

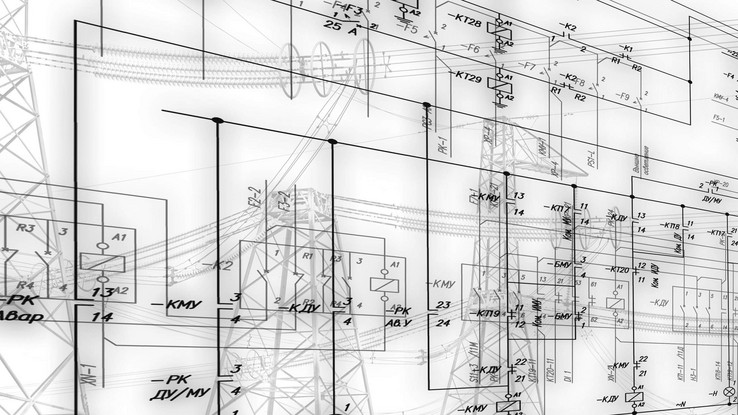

Hundreds to thousands of components must be described and designed, numbered and connected to one another with cables and wires. The cable and wires, in turn, must be laid out with cross-sections and lengths and be assigned colours and identifying markers. Schematics are documented across thousands of pages. To keep track of everything, navigating within the diagrams must be ensured by creating cross-references. A digital prototype can be used to support manufacturing control cabinets. Ultimately, the system’s functionality must comply with the specifications and be transportable.

Tasks for Electrical Engineering

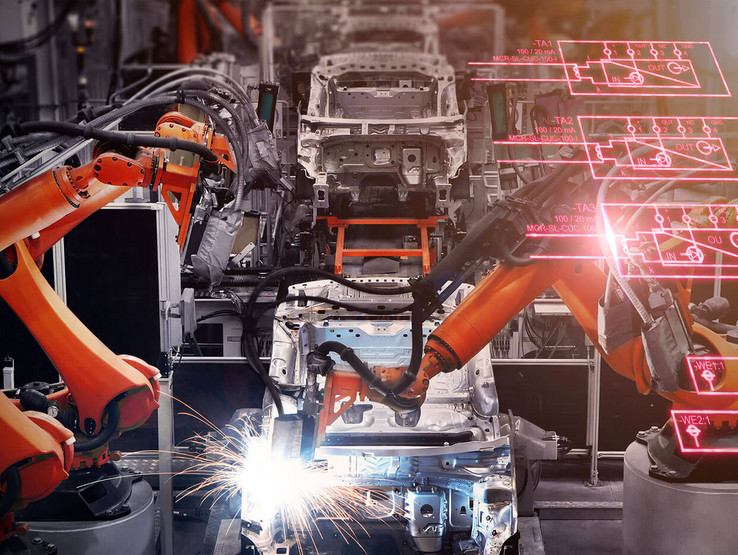

Electrical engineering comprises a broad range of engineering tasks. They include designing power supplies for actuators, sensors and control technology as well as developing control systems for machines and plant systems. In addition, protective systems against overvoltage and overloads must be developed and the systems need to be earthed. Another important area of activity is creating a variety of documentation, especially schematics to record the connection of the various electrical components. Creating the manufacturing documentation for building the control cabinets that hold the components is yet another daily task. All of this taken together supports users, from commissioning and startup to tasks in service and maintenance.

Bringing Order to Your Engineering

There must be order, even in engineering. Using EPLAN solutions, your work conforms to international codes, standards and guidelines.

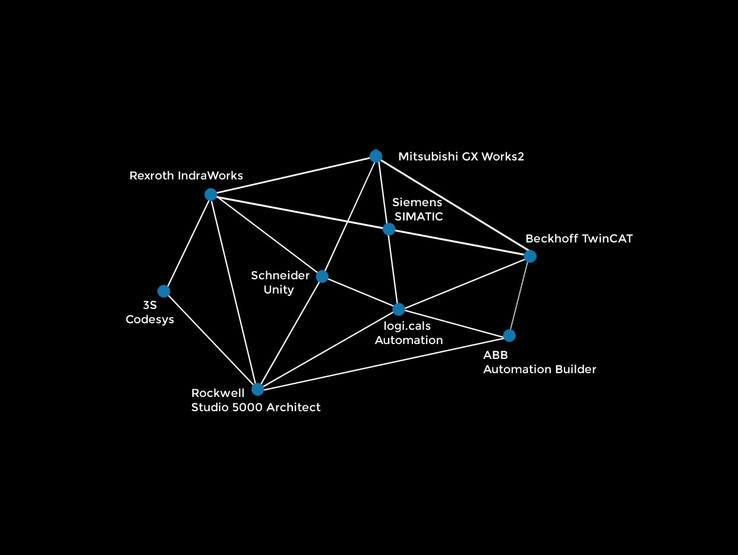

EPLAN Offers Integrated Solutions for Electrical Engineering

Engineering software for integrated planning and processes in electrical engineering is one of our core skills. Take advantage of our many years of experience and high-quality solutions!